The "regular warehouse" I'm referring to isn't a leaky, dilapidated shed, nor a damp, stuffy basement. It needs to be a place that provides shelter from the wind and rain, good ventilation, stable temperature, and no obviously corrosive gases—like a dry warehouse for storing rice and flour. If the warehouse itself is damp and sunny, not only petroleum resin, but anything will spoil easily over time. So, how long can Petroleum Resins actually last in such a suitable regular warehouse without spoiling?

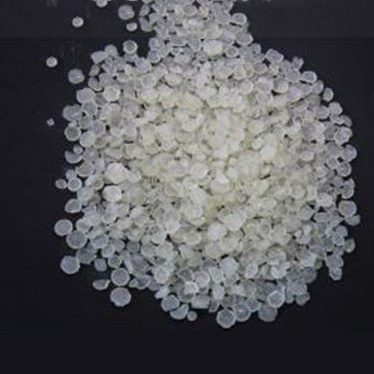

First, let's talk about the fact that Petroleum Resins are solid granules or blocks, unlike liquids which are more delicate, and their chemical properties are quite stable. Like table salt or sugar, they don't easily spoil unless you handle them improperly. Unlike fruit that rots after a few days, or bread that easily molds, they naturally have a good foundation for long-term storage. This is the key reason why they can last for a considerable time in a regular warehouse.

Although Petroleum Resins are durable, there are a few details to keep in mind when storing them in a regular warehouse, otherwise they can easily spoil prematurely. First, prevent moisture. The warehouse floor should not be damp. It's best to place the resin on pallets, not directly on the ground, otherwise moisture will seep in and cause the resin to clump. Second, prevent high temperatures. In summer, the warehouse should not be stuffy like a sauna. Temperatures exceeding 35℃ are not ideal, as they can cause the resin to soften and stick together. Also, do not store them with strong acids, alkalis, or corrosive substances, just like you wouldn't put vinegar and baking soda together, to avoid reactions. Following these points will significantly extend the storage time.

How can you tell if Petroleum Resins have spoiled after being stored for a while? You don't need professional instruments; you can judge by sight and touch. If you notice that your Petroleum Resins have darkened to a blackish color, instead of their original pale yellow or yellowish-brown, they're likely spoiled. Also, check the odor; if they're severely clumped and so hard you can't even tap them, or if they crumble into a thin paste without their original granular texture, something's wrong. Finally, smell them; if they have a pungent, unpleasant odor, unlike their original light resinous smell, they've likely deteriorated. Deteriorated Petroleum Resins have poor adhesion and reduced performance, so they shouldn't be used.

In a properly maintained, ordinary warehouse, provided there's proper moisture control, ventilation, and protection from high temperatures, and they're not stored with corrosive substances, Petroleum Resins can generally be stored for 12 to 24 months, or 1 to 2 years. With better warehouse conditions, such as proper cooling in summer and frequent ventilation, they might last for more than 2 years. However, in a damp warehouse or with frequent high temperatures in summer, they may clump and deteriorate in less than a year. Simply put, it's like storing dried goods; if you store them carefully, they can last a long time.